喷漆的过程:

工业喷漆是一种涉及使用专用设备和材料将涂层涂覆在表面的过程。这种涂层可以应用于各种材料,包括金属、塑料和木材,并用于装饰。喷漆过程通常涉及几个步骤,包括表面处理、涂层应用和固化。

表面处理:在实际喷涂过程开始之前,必须对表面进行适当的准备。这包括清洁和脱脂表面,以去除任何可能干扰涂层附着力的污垢或碎屑。此外,必须去除任何锈蚀或腐蚀,并且必须打磨表面以形成光滑、均匀的表面。

涂层的应用:一旦表面准备好,就可以开始实际的喷涂过程。这通常涉及使用喷枪在表面上涂上一层薄而均匀的涂层材料。根据所使用的涂层类型,可能需要多层涂层才能达到所需的厚度和覆盖范围。

固化:涂覆涂层后,必须允许其固化。这涉及将涂层表面暴露在热或空气中,以使涂层干燥和硬化。在某些情况下,涂层可以在烤箱中烘烤以加快固化过程。

喷漆的优点:

工业喷漆的一个关键优势是其速度和效率。由于涂层可以快速均匀地涂覆,因此可以在相对较短的时间内涂覆大量零件或产品。这有助于降低生产成本并提高产量。

工业喷漆的另一个优点是其多功能性。喷漆可用于应用各种涂料,包括油漆、底漆、密封剂和粘合剂。这使其成为各种应用的有用工具,从汽车和航空航天制造到家具生产等等

总体而言,工业喷漆是一种多功能且高效的工艺,在各种制造和生产环境中发挥着重要作用。

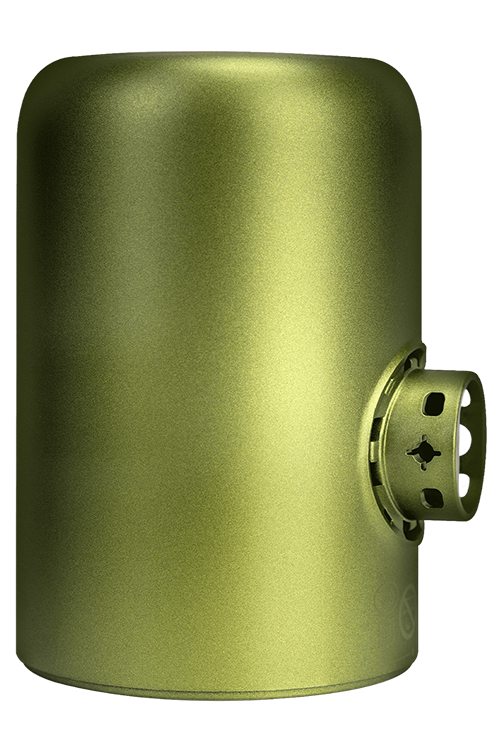

我们的喷涂工艺:

雅卓涂装事业部,拥有多条两喷三烤,三喷四烤涂装线。

涂装线体采用德国西门子电控设备及系统;

选用固瑞克进口油泵供油,保证送漆量稳定;

每个喷房搭配日本进口蓝枪进行涂装作业;

拥有可调可变先进光固化设备对产品表面进行固化。

我们能够满足客户多元化需求