The process of spray painting:

Industrial spray painting is a process that involves using specialized equipment and materials to apply a coating to a surface. This coating can be applied to a variety of materials, including metal, plastic, and wood, and is used for both decorative and functional purposes. The spray-painting process typically involves several steps, including surface preparation, application of the coating, and curing.

Surface Preparation: Before the actual spraying process can begin, the surface must be properly prepared. This includes cleaning and degreasing the surface to remove any dirt or debris that could interfere with the adhesion of the coating. In addition, any rust or corrosion must be removed, and the surface must be sanded to create a smooth, even surface.

Application of the Coating: Once the surface is properly prepared, the actual spraying process can begin. This typically involves using a spray gun to apply a thin, even layer of the coating material onto the surface. Depending on the type of coating being used, multiple coats may be required to achieve the desired thickness and coverage.

Curing: After the coating is applied, it must be allowed to cure. This involves exposing the coated surface to heat or air to allow the coating to dry and harden. In some cases, the coating may be baked in an oven to speed up the curing process.

The advantages of spray painting:

One key advantage of industrial spray painting is its speed and efficiency. Because the coating can be applied quickly and evenly, large volumes of parts or products can be coated in a relatively short amount of time. This can help to reduce production costs and increase throughput.

Another advantage of industrial spray painting is its versatility. Spray painting can be used to apply a wide range of coatings, including paints, primers, sealants, and adhesives. This makes it a useful tool for a variety of applications, from automotive and aerospace manufacturing to furniture production and beyond.

Overall, industrial spray painting is a versatile and efficient process that plays an important role in a variety of manufacturing and production settings.

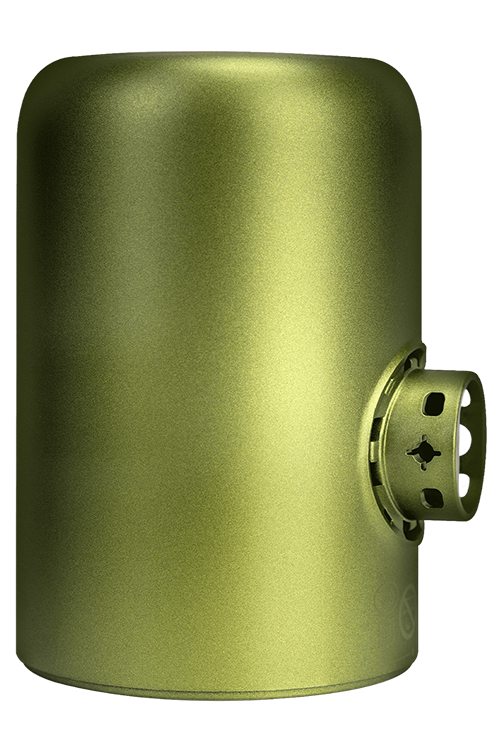

Our spray painting process:

YAJOY Painting Division has a number of 2 paint 3 bake, 3 paint 4 bake spraying lines.

Our Spray painting lines employ components of the most well-known manufacturers in the world, such as Siemens and Graco. This way we can ensure stable paint delivery , even coverage, as well as precise processes and near-zero deviations.

Advanced, adjustable light curing equipment completes the equipment needed to create the highest standards – everytime and anytime!